eFOUP Wafer Handling

Introduction to Enhanced Wafer Handling with ePAK’s eFOUP

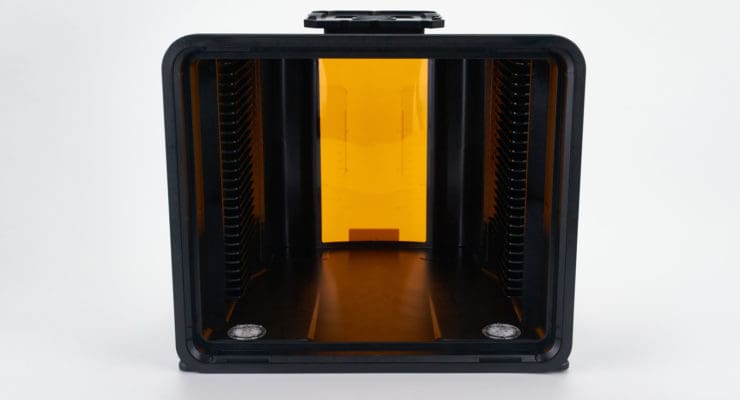

In the semiconductor industry, efficient and safe wafer handling is crucial for maintaining high production yields and ensuring the integrity of delicate wafers. ePAK’s eFOUP (Front Opening Unified Pod) is designed to meet these stringent requirements by providing robust protection and easy access to wafers during transport and storage. The essential need for an automated material handling system (AMHS) to transport FOUPs in semiconductor fabrication facilities cannot be overstated, as it ensures the safe and efficient movement of these critical storage units.

Download Catalog Contact UsOverview of eFOUP Technology

Key Features- SEMI/FIMS compliant

- AMHS compliant

- Automated operation minimizes potential contamination from human interaction

- Automation compatibility for opening and closing

- Ultrapure, low outgassing materials protect wafers

- Robust wafer retention ensures reduced particle generation

- Multiple purge position options

- Multiple handle options

- Multiple window options

- Coupling plates for positioning the FOUP on a load port and enabling transfer by the AMHS

eFOUP Specifications

- Wafer size – 300mm

- Capacity – 25 slot

- All datums established relative to kinematic coupling per SEMI

- Wafer spacing – 10mm (+/-0.5mm wafer-to-wafer, non-cumulative)

- Weight (empty) – 4.6 kg; 25 wafer loaded in, about 7.8kg

- Overall size w/ handles and robotic flange : W420 X L342 X H338(mm)

- Overall size w/o handles and robotic flange : W388 X L342 X H332(mm)

Features of eFOUP

Environmental Control and Purge OptionsPurge Systems: Offers purge options with two or four ports to maintain inert atmosphere conditions, replacing ambient air with nitrogen to protect wafers from oxidative damage. Additionally, a FOUP stocker can be used for managing and storing FOUPs, applying purge gas to increase device yield.

While FOUPs are designed for 300mm wafers, SMIF pods are suitable for wafers with dimensions smaller than 300mm. Both systems play a crucial role in maintaining cleanliness and reducing particle contamination during the handling of silicon wafers.

ESD Protection: Integrated features for electrostatic discharge protection, critical for maintaining the integrity of wafers during storage and transport.

Frequently asked questions

What is a FOUP?

The manufacturing process of FOUPs is crucial in safeguarding semiconductor wafers from contamination and damage during semiconductor wafer manufacturing.

What is the difference between FOUP (front opening unified pod) and a FOSB (front opening shipping box)?

How many wafers can a FOUP hold?

What is the difference between FOUP and SMIF pods?

A wafer FOUP is a specialized container designed to safely transport 300mm silicon wafers within automated material handling systems (AMHS). FOUP is specifically designed to accommodate 300mm wafers, which have become the standard in modern semiconductor manufacturing. The increased size and flexibility of 300mm wafers made it challenging to apply the same SMIF technology and design used for smaller wafers. As a result, the FOUP was developed to address the unique requirements of handling 300mm wafers.

SMIF Pods: Ideal for Wafers Less Than 300mm

In contrast, SMIF pods are suitable for wafers with dimensions smaller than 300mm. These pods have been widely used in the semiconductor industry for many years and have proven to be effective in protecting and transporting wafers during the manufacturing process.

SMIF Pods: Ideal for Wafers Less Than 300mm

In contrast, SMIF pods are suitable for wafers with dimensions smaller than 300mm. These pods have been widely used in the semiconductor industry for many years and have proven to be effective in protecting and transporting wafers during the manufacturing process.

Wafer Shipping & Handling Catalog

Our catalog covers a wide range of products specifically tailored to handling your wafers. Please contact us if you need custom solutions to your projects.