eFOSB Wafer Handling

Introduction to Enhanced Wafer Handling with ePAK’s Front Opening Shipping Box (eFOSB)

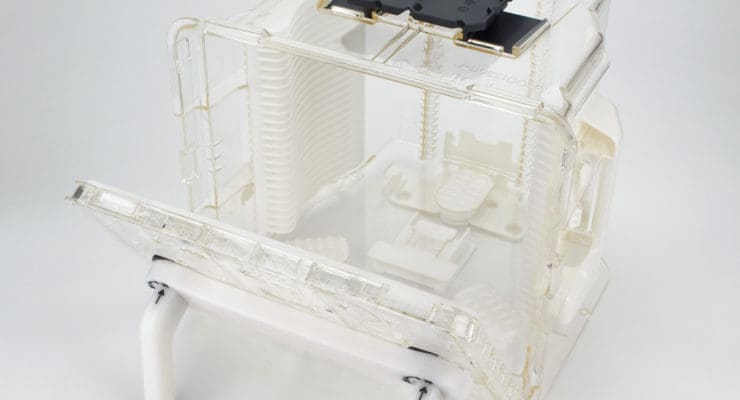

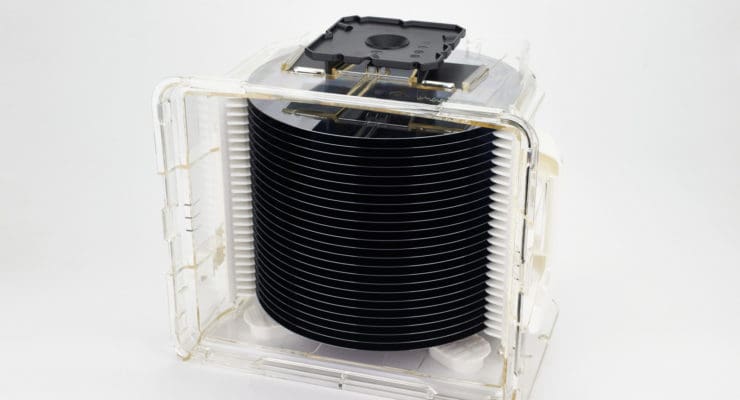

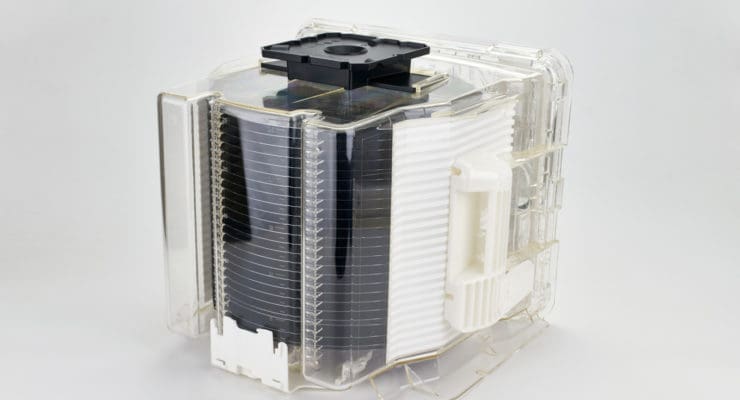

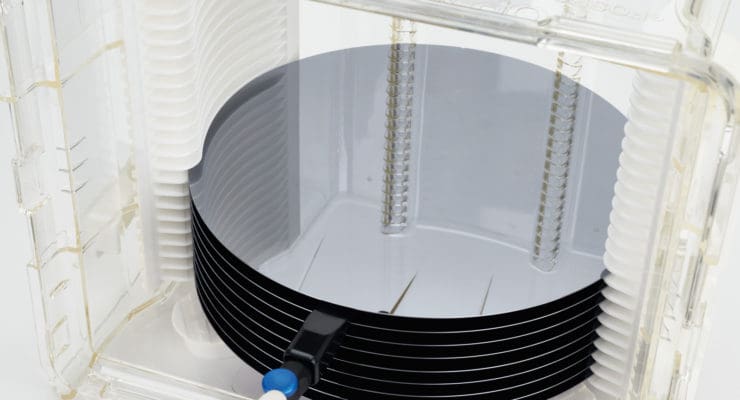

The ePAK eFOSB (Front Opening Shipping Box) enhances 300mm wafer handling and shipping for semiconductor manufacturing. Compliant with SEMI/FIMS and AMHS standards, this FOSB ensures superior protection during transport and storage. The eFOSB features a 25-slot capacity for 300mm wafers with precision spacing, automated operations, and a manual handling option. Crafted from ultra-clean, low-outgassing materials with a robust wafer retention system, it minimizes contamination risks and particle generation, preserving wafer integrity. This FOSB offers immediate availability, streamlined production, and customization options, making it ideal for semiconductor manufacturers seeking to optimize their wafer handling and shipping processes.

Download Catalog Contact UsOverview of eFOSB Technology

Key Features of eFOSB Technology:

- SEMI/FIMS compliant

- AMHS compliant

- Automated operation minimizes potential contamination from human interaction

- Automation & manual compatibility for opening and closing

- Ultrapure, low outgassing materials protect wafers

- Robust wafer retention ensures reduced particle generation

- The eFOSB features a 25-slot capacity for 300mm wafers with precision spacing, automated operations, and a manual handling option. FOSB semiconductor solutions are essential for the safe transportation and storage of delicate semiconductor wafers, driven by advancements in technology and the increasing complexity of semiconductor devices.

eFOSB Specifications

- Wafer size – 300mm

- Capacity – 25 slot

- All datums established relative to kinematic coupling per SEMI

- Wafer spacing – 10mm (+/-0.5mm wafer-to-wafer, non-cumulative)

- Weight (empty) – 4.9 kg; 25 wafer loaded in, about 8.1kg

- Overall size w/ handles and robotic flange : W395 X L340 X H338(mm)

- Overall size w/o handles and robotic flange : W388 X L340 X H333(mm)

eFOSB 300-A Interoperability

eFOSB Shell Interface Features:- Kinematic coupling features

- Alignment

- Wafer position reference plane

- Hold down feature

- Load port pulls down on feature to hold eFOSB

- Registration pin holes

- Alignment

- Latch key holes

- Allows door to be mechanically latched and unlatched

Strategic Advantages

Readiness and Competitive BenefitsImmediate Availability: eFOSB units are ready for immediate shipment, supporting rapid deployment to accelerate your manufacturing capabilities without delay.

Streamlined Production and Supply Chain: Leveraging advanced manufacturing technologies and robust supply chain logistics, ePAK ensures that eFOSB can be produced and delivered swiftly. Our operations are designed to respond dynamically to both market fluctuations and specific client requirements.

Customization for Precision Fit: eFOSB can be tailored to meet specific operational needs, offering flexible solutions that reduce downtime, minimize maintenance costs, and enhance wafer protection.

Frequently asked questions

What is FOSB?

What are the applications for a FOSB?

- Secure wafer handling and transportation

- Clean and contamination-free wafer handling

- Reliable automation interface and interoperability in semiconductor manufacturing

- Long-distance shipping of wafers between facilities

- Temporary storage of wafers in cleanroom environments

What is the difference between FOUP (Front Opening Unified Pod) and a FOSB (Front Opening Shipping Box)?

How many wafers can a FOSB hold?

What is the difference between FOSB and SMIF pods?

- FOSBs are designed for long-distance shipping and external transport of wafers.

- SMIF pods are typically used for short-distance transport within a cleanroom or between closely located tools.

- FOSBs usually have a larger capacity and more robust construction for shipping purposes.

- SMIF pods are generally smaller and designed for quick, easy access in cleanroom environments.

What are the key features of ePAK's eFOSB?

- SEMI/FIMS and AMHS compliant

- Automated operation to minimize contamination

- Compatible with both automated and manual handling

- Constructed from ultrapure, low outgassing materials

- Robust wafer retention system for reduced particle generation

- Precision wafer spacing of 10mm (+/-0.5mm wafer-to-wafer, non-cumulative)

What are the dimensions and weight specifications of the eFOSB?

- Overall size with handles and robotic flange: 395mm (W) x 340mm (L) x 338mm (H)

- Overall size without handles and robotic flange: 388mm (W) x 340mm (L) x 333mm (H)

- Weight (empty): 4.9 kg

- Weight (loaded with 25 wafers): approximately 8.1 kg

How does the eFOSB ensure wafer protection during transport?

Can the eFOSB be customized for specific operational needs?

What are the advantages of using ePAK's eFOSB?

- Immediate availability for rapid deployment

- Streamlined production and supply chain for swift delivery

- Customization options for a precise fit to operational needs

- SEMI/FIMS and AMHS compliance for seamless integration

- Advanced design for superior wafer protection and contamination control

Wafer Shipping & Handling Catalog

Our catalog covers a wide range of products specifically tailored to handling your wafers. Please contact us if you need custom solutions to your projects.