Wafer Handling Products

Device protection and contamination control begins at the wafer fab and extends to the assembly site. ePAK never forgets that the most valuable product in the semiconductor and electronics industry is also the most fragile and susceptible to mishandling and contamination. Not all wafers are created equal…with back-grinding, unique material sets, and exotic semiconductor processes, one product does not fit all wafers. From ePAK's most advanced eLX wafer canisters to cost efficient wafer jars, ePAK tailor fits our products to meet your requirements.

Products

eSiC: Silicon Carbide Wafer Handling

eSiC: Silicon Carbide Wafer Handling

Ensuring Reliability in High-Performance Silicon Carbide Applications

Introduction to eSiC Wafer Handling Solutions

As silicon carbide (SiC) technology continues to drive advancements in high-temperature and high-frequency devices, ePAK’s eSiC wafer handling solutions offer critical protection and precise handling for silicon carbide wafers in applications such as power electronics, renewable energy systems, and electric vehicles.

Our eSiC solutions are meticulously engineered for SiC wafers, offering advanced protection against surface defects, contamination, and physical stress. This ensures greater efficiency and superior performance in the semiconductor industry and enhances the reliability of SiC-based devices in demanding conditions.

As a material, silicon carbide is valued for its high-temperature resilience, excellent thermal conductivity, and robust structural integrity. However, SiC wafers also require careful handling to avoid damage during manufacturing and transport stages.

ePAK’s eSiC solutions offer tailored protection to meet these needs, enabling safer, contamination-free handling across each stage of silicon carbide wafer processing. Our comprehensive solutions support SiC production from boule growth to wafer dicing and final packaging.

eFOSB Wafer Handling

eFOSB Wafer Handling

Introduction to Enhanced Wafer Handling with ePAK’s Front Opening Shipping Box (eFOSB)

The ePAK eFOSB (Front Opening Shipping Box) enhances 300mm wafer handling and shipping for semiconductor manufacturing. Compliant with SEMI/FIMS and AMHS standards, this FOSB ensures superior protection during transport and storage. The eFOSB features a 25-slot capacity for 300mm wafers with precision spacing, automated operations, and a manual handling option. Crafted from ultra-clean, low-outgassing materials with a robust wafer retention system, it minimizes contamination risks and particle generation, preserving wafer integrity. This FOSB offers immediate availability, streamlined production, and customization options, making it ideal for semiconductor manufacturers seeking to optimize their wafer handling and shipping processes.

eFOUP Wafer Handling

eFOUP Wafer Handling

Introduction to Enhanced Wafer Handling with ePAK’s eFOUP

In the semiconductor industry, efficient and safe wafer handling is crucial for maintaining high production yields and ensuring the integrity of delicate wafers. ePAK’s eFOUP (Front Opening Unified Pod) is designed to meet these stringent requirements by providing robust protection and easy access to wafers during transport and storage. The essential need for an automated material handling system (AMHS) to transport FOUPs in semiconductor fabrication facilities cannot be overstated, as it ensures the safe and efficient movement of these critical storage units.

Wafer Interface Materials

Wafer Interface Materials

ePAK Offers the Full Set of Inter Carrier Materials

-

Interleaf or Wafer Separators

-

High-Purity

-

Conductive materials

-

Tyvek® Interleaf

-

Cushion Disks & Edge Protector

-

Closed Cell Foam (Conductive and Anti-Static Materials)

-

ePAD® cushioning (high purity replacement to foam)

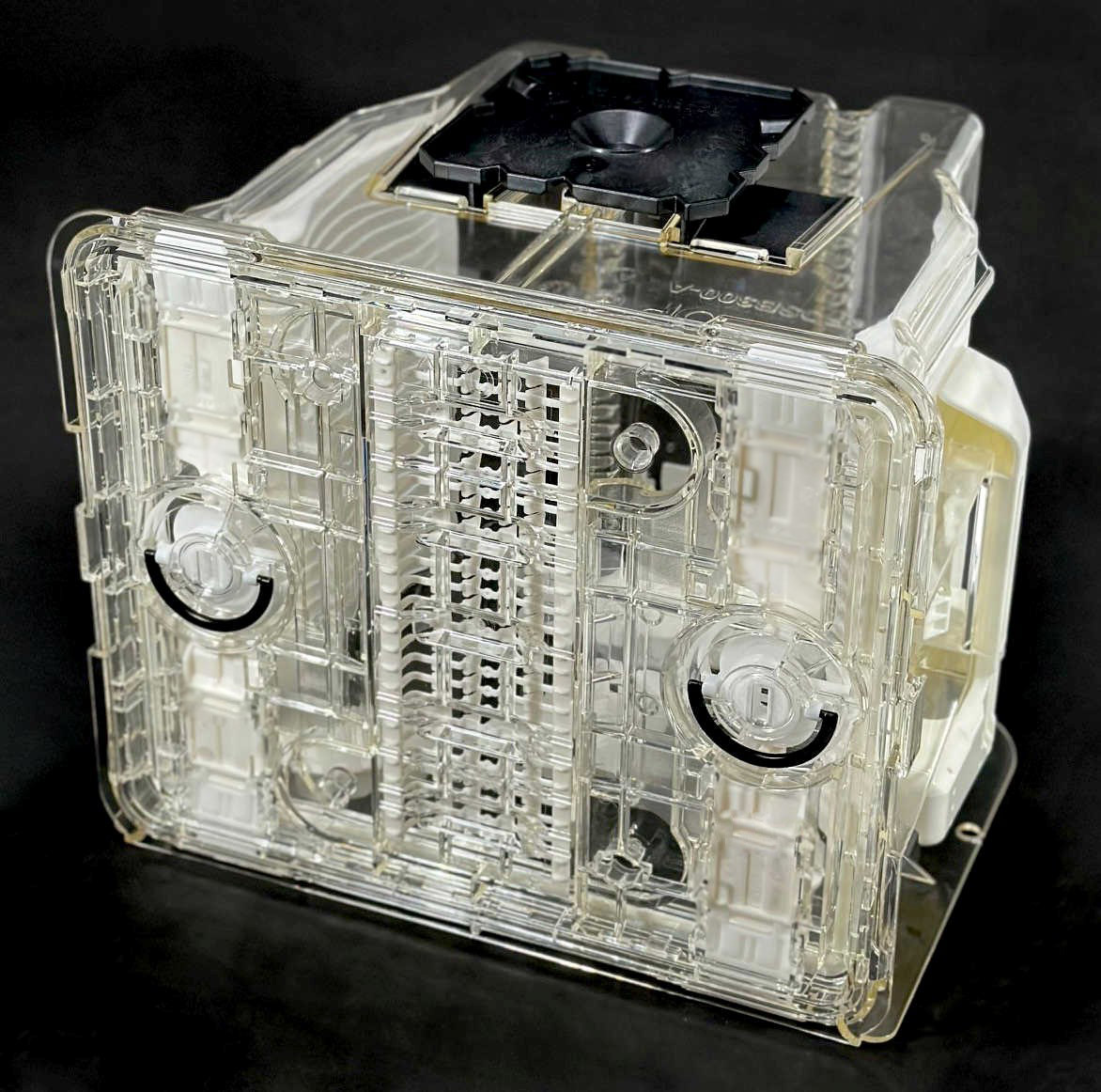

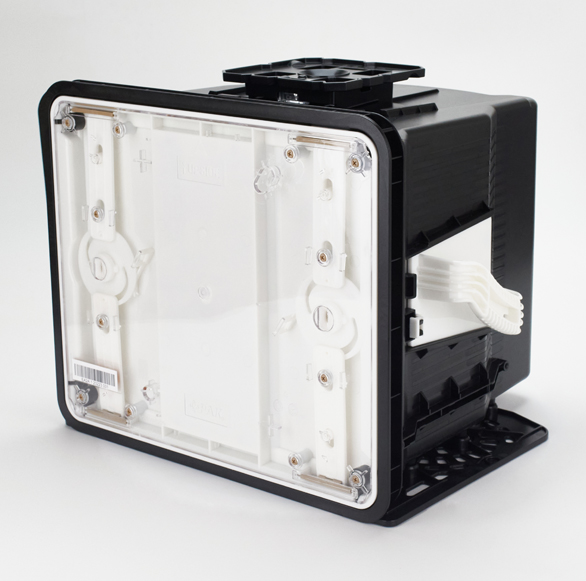

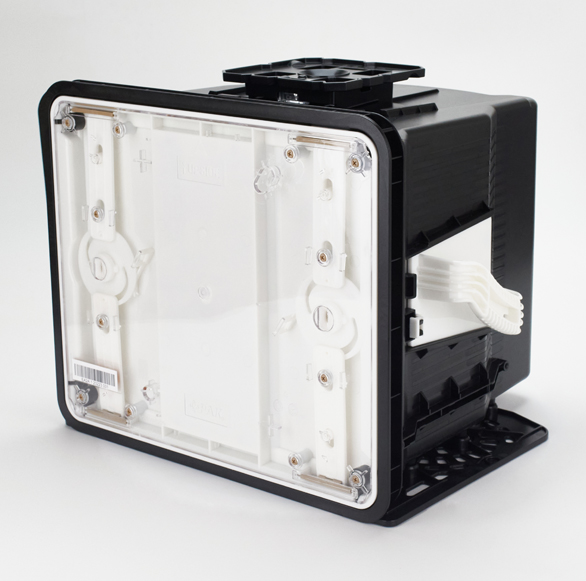

eLX™ Zero-Movement Canisters

eLX™ Zero-Movement Canisters

The ultimate in wafer shipping. ePAK’s patented design combines the best performance features of vertical cassettes and old style coin-stack shippers

-

Best overall wafer protection with the lowest cost of ownership in the industry

-

Ultimate in wafer breakage protection

-

Bond pad and bump integrity through zero-inter-wafer movement feature

-

Interfaces with leading automated equipment

ePRO™ Shipping Boxes

ePRO™ Shipping Boxes

Engineered for the vertical shipping of 25 wafers per box

-

Available in 4”, 5”, 6” & 8” sizes

-

Multiple designs of cushions and cassette slot sizes

-

Ultra clean Materials to meet your specification

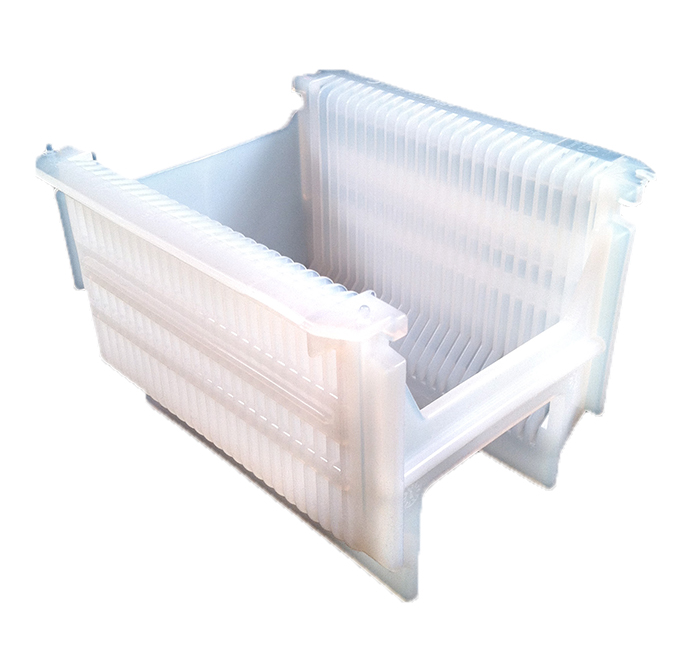

Process Boats and Boxes

Process Boats and Boxes

In Process handling of wafers with standard machine interface

-

Full range of materials to meet your In-Process needs

-

Custom designs available

Flex Frames and Shippers

Flex Frames and Shippers

Metal & Plastic Flex Frames and Shippers

-

Full Range of sizes and materials

-

Vacuum-formed & Injection molded Shippers

-

Single and Multiple Frame shipper designs available

Hoop Rings and Shippers

Hoop Rings and Shippers

Full Range of sizes, custom colors available

-

Vacuum-formed single Shippers

-

Injection Molded Multishippers

Single Wafer Shippers

Single Wafer Shippers

For 1, 2, 3, 4, 5, 6, 8, and 12 inch inch wafers, up to the 450mm wafer, ePAK has industry approved Coinstyle or Clamshell solutions.

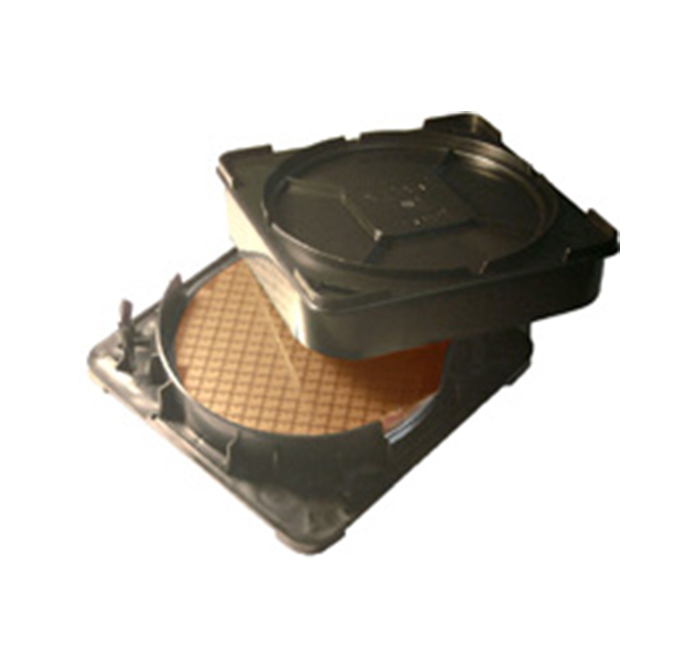

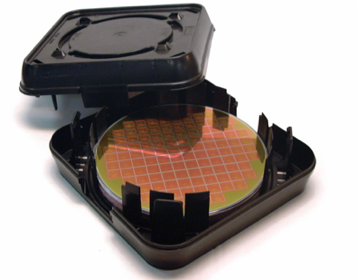

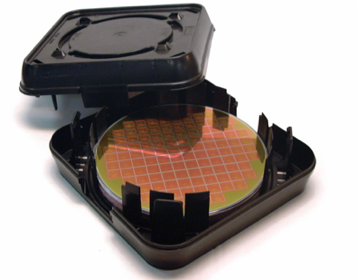

eCT Standard Wafer Canisters

eCT Standard Wafer Canisters

Horizontal “coin stack” type shippers.

- Enhanced protection for standard and thinned wafers

- Sizeable savings from increased packing density

OverPaks™

OverPaks™

Container shipping products designed to protect your enclosed devices while in transit.

-

Many designs and matrix available

-

Custom designs can be done to meet your shipping requirements

eJR Wafer Jars

eJR Wafer Jars

A full range of Jar sizes and foam inserts are available.

- Maximum Packing Density

- Lowest Cost Wafer Handling

ePAD™

ePAD™

Revolutionary cushioning option replaces dirty foams to form a system eliminating corrosion and organic contaminants

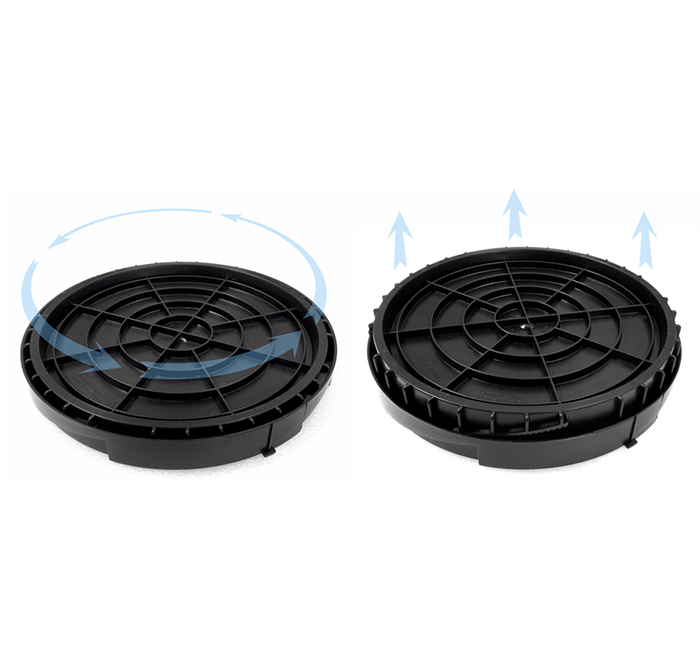

eFORM™

eFORM™

Patented adjustable spacer option that enhances wafer protection by controlling packing process variability and minimizing vertical movement.

Wafer Shipping & Handling Catalog

Our catalog covers a wide range of products specifically tailored to handling your wafers. Please contact us if you need custom solutions to your projects.